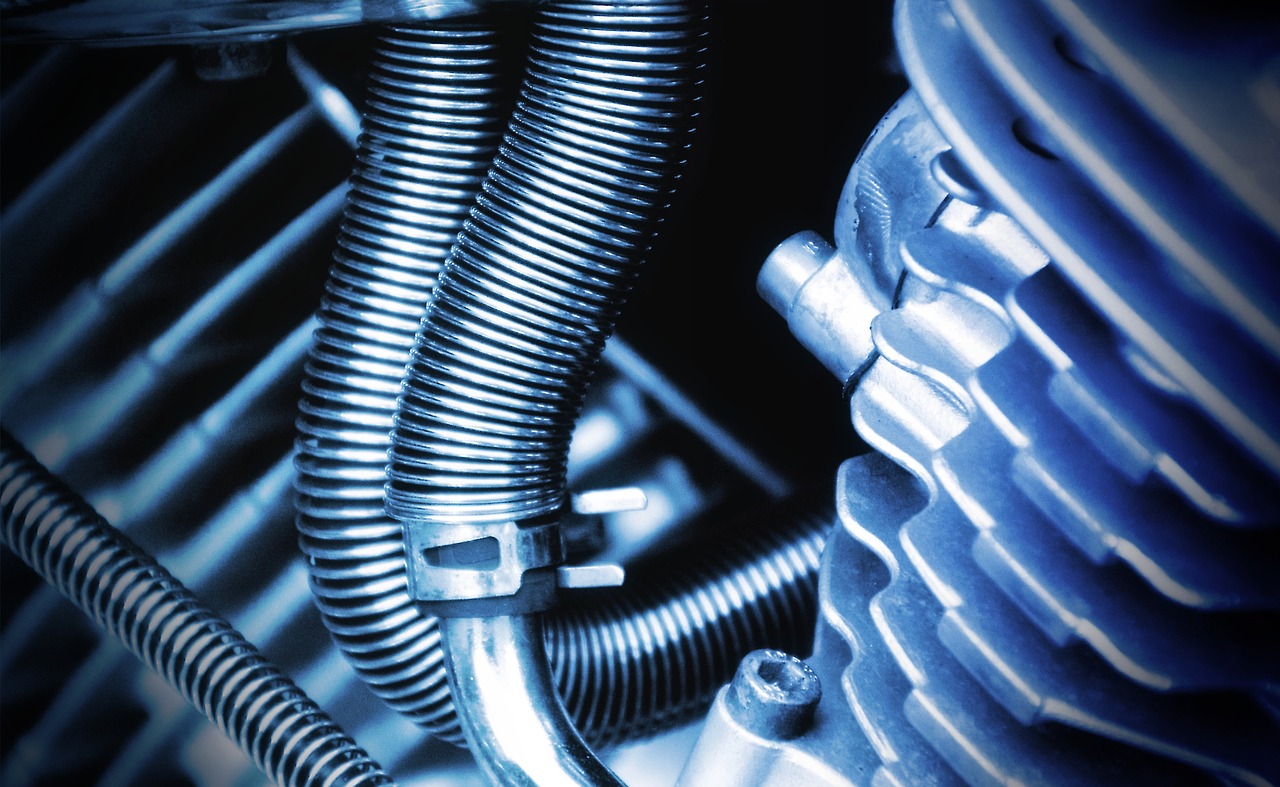

A hydraulic hose is specifically designed to convey hydraulic fluid to or among hydraulic components, valves, actuators and tools. Since operating at high pressure, hydraulic hose are often reinforced and constructed with several layers whilst remaining flexible. This post will provide you with the essential information you need to know about hydraulic hoses. This includes looking at the hydraulic hoses and fittings as well as the cost of purchasing a hydraulic hose.

Basic Modern Hydraulic Hose Construction

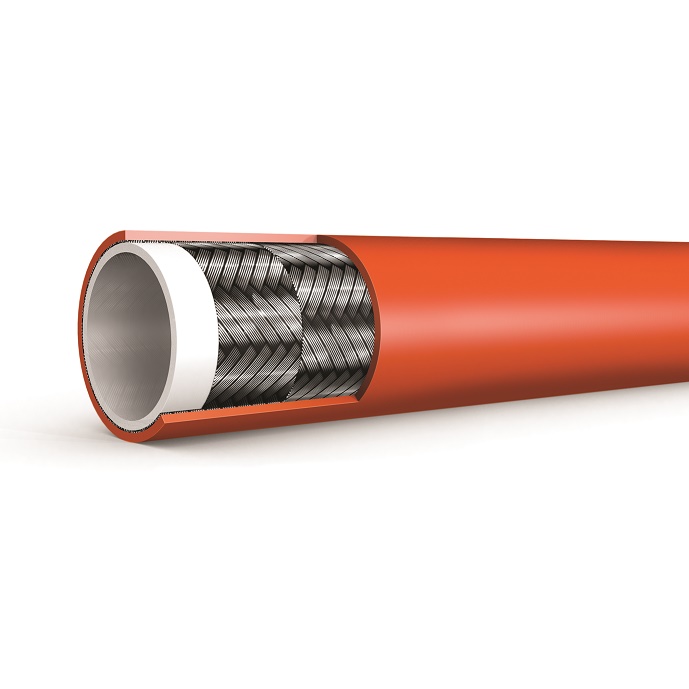

The basic hydraulic hose is constructed of three layers. These layers help maintain a consistent and reliable flow of liquid whilst protecting the hose from breaking down.

- Inner Tube: The inner tube is often made from PDFE, thermoplastic or synthetic rubbers. This tube is designed to allow free-flowing elasticity and pressure-resistant bearing whilst being compatible with the liquid it carries.

- Reinforcement Layer: Comprised of a coil or braided wire. The reinforcement layer surrounds the inner tube, supporting the tubing whilst protecting against tears.

- Outer Layer: Made of rigid materials, this layer is designed to protect the innards of the hydraulic hose.

Hydraulic Hose Liquids

There are three main types of liquid that can run through a hydraulic hose, including:

- Synthetic Oil

- Petroleum Oil

- High- water content liquid.

Most hydraulic hoses are capable of transporting petroleum oil and high-water content liquids; however synthetic oils require specific hose materials.

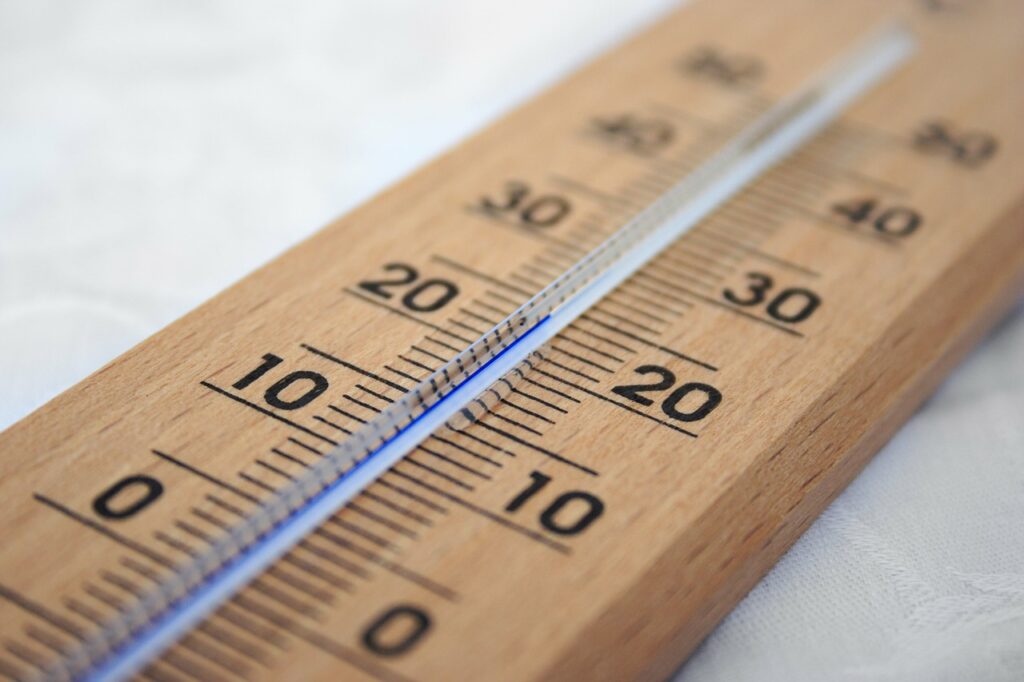

Hydraulic Hose Temperature

Hydraulic hoses are exposed to two temperatures: internal liquid temperature and the external working temperature. For that reason, hoses are rated for performance of both temperatures with a maximum and minimum functioning temperature. If these ratings are exceeded, the hoses’ working life can be severely reduced or even cause failure.

Hydraulic Hose Pressure

Hydraulic hoses work at high/ very pressures; they are designed to withstand this pressure externally and internally to the minimum and maximum. Exceeding these pressure ratings can severely affect the hose performance. Pressure recommendations for a specific type of hose are usually available from the manufacturer.

Hydraulic Hose Applications

Due to the rigidity of pipes and tubes it can be difficult to use them in moving operations. For example, a construction digger that requires a hydraulic system but also requires the freedom of movement to operate the tool can place limitations on hydraulic connections. Therefore a hydraulic pipe can allow flexibility and elasticity in tool arm movement that is unavailable with tubes or pipes.

Some hydraulic systems can benefit from a combination of pipes, tubes and hoses. Large complex vehicles like planes require hydraulics to operate wing movements and landing gear therefore using multiple hydraulics systems can help achieve the movement of the plane.

General rule of thumb for hydraulic hose installation is matching the type of hose to the machine contour. For more information check out our previous blog post.

Hydraulic Hose Cost

Don’t judge a hose by its price. Hose pricing can vary quite dramatically. A standard product is likely to be the cheapest but premium products may be worth it as they can provide double the lifespan. When buying a hydraulic hose there are more factors to consider other than the price such as life span. This may save you time and money in the future.

Hydraulic Hose Fittings

There are six main types of threads commonly used on hydraulic hose fittings:

- UN/UNF

- NPT/NPTF

- BSPP (BSP. Parallel)

- BSPT (BSP, Tapered)

- Metric Parallel

- Metric Tapered

Identifying the correct thread is crucial for selecting the correct replacement parts for maintenance and repair of a hydraulic hose. Selecting the wrong part can compromise the pressure holding capacity and seal reliability of the hydraulic hose fitting and adapter. Check our blog for more information.

Hose Shop are the leading supplier of hydraulic hoses, check out our previous blogs or get in touch to find the right hydraulic hose for you!