Even if you are not aware of what a hose coupling is, the odds are that you have seen or used one before. So, first and foremost, what is a hose coupling?

A hose coupling is a piece of equipment used to connect a hose with something else, like a tap, sprinkler, pump or another hose. For example, a coupling can be used to connect a plastic garden hose to your outside tap.

The hose is used to transport a variety of different things, from water and air through to chemicals and gases, so the hose coupling needs to be able to withstand this.

Hose couplings can also be known as hose fittings, hose connectors or hose adaptors.

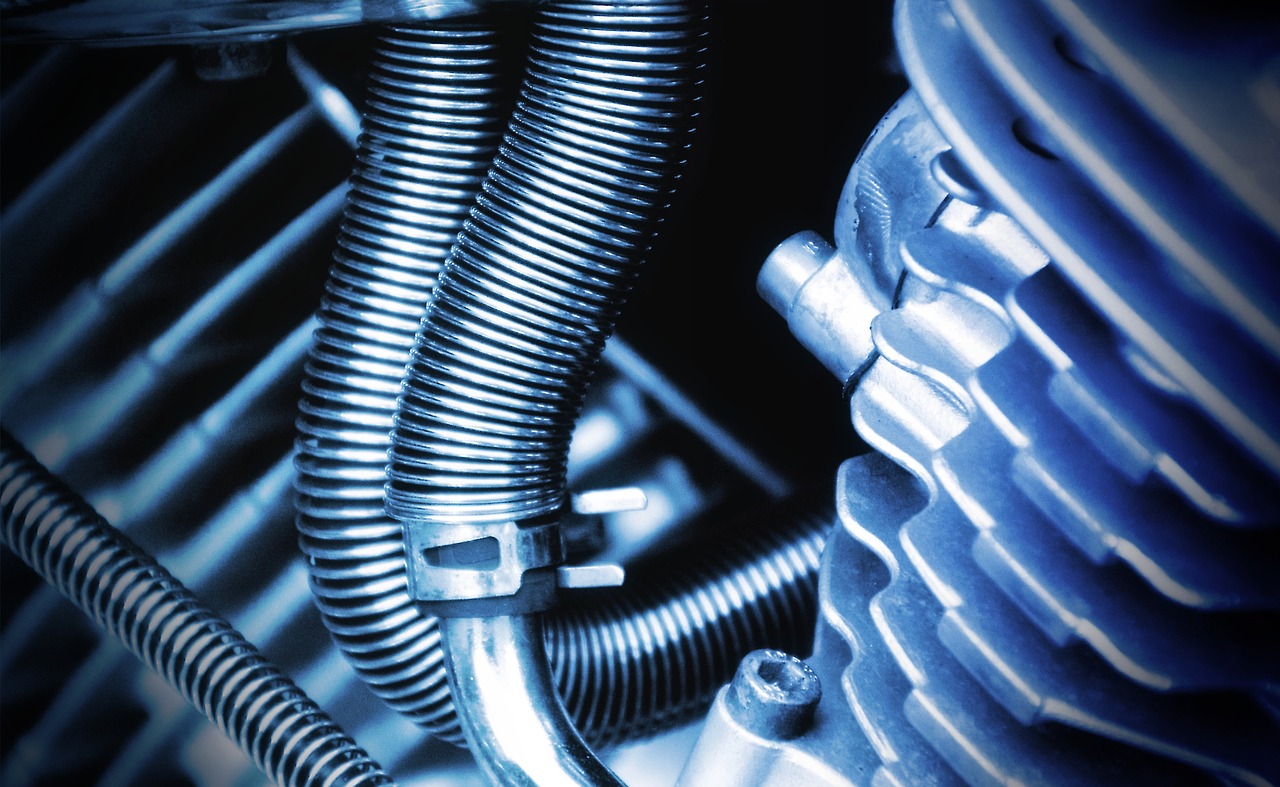

What are hose couplings made of?

Hose couplings come in a variety of different materials including steel, brass, plastic, stainless steel and aluminium. The coupling used will depend on what the hose is being used for and what it is connected to.

For example, plastic couplings are conventionally used with garden hoses as they are cheap to manufacture and do not react to water. However, they can crack and break easily.

Stainless steel couplings are expensive but can withstand extreme temperatures as well as high pressure so are common in industrial settings

Aluminium fittings are light and water-resistant, so are used where low weight and durability are essential, like cars and planes.

Even if hose couplings are made from durable materials, we recommend storing a few spares so if one breaks, it can be fixed easily without disruption.

What is the difference between male and female hose couplings?

All couplings have a male and female half, the male half fits inside the female half to create the complete coupling. Couplings also have what are known as ‘threads’ on them, which allow couplings to connect to each other securely. Female couplings have threads on the inside, and male couplings have threads on the outside, ensuring that they can easily and tightly connect.

As well as male and female couplings, you can get ‘genderless’ hose couplings that can be connected to any type of coupling.

The coupling should have its ‘gender’ labelled on it in an easily accessible place, alongside the size of the thread.

What types of coupling are there?

As well as being made of various materials and having threads of different sizes and in different places, there are several varieties of hose coupling. Choosing the wrong coupling can cause leaks and pressure loss, as well as be a potential health and safety risk.

Couplings need to create a tight seal, so there are a variety of different sizes and angles of coupling to ensure a good fit.

Depending on what is transported in the hose, different couplings need to withstand various pressures, which is measured in ‘bars or psi’.

‘Instantaneous’ couplings are specialist couplings used in high-pressure water systems such as fire hoses. They are held together by spring-operated catches that can withstand a high amount of pressure but can flex with the hose and be easily attached and disconnected as needed.

Some couplings are advertised as ‘quick release’ so the connection can be quickly disconnected if needs be. This is common if the connection is only intended to be temporary or needs to be rapidly severed if there is a health and safety concern. Conversely, coupling connections that need to last will be taped or crimped together to reduce the possibility of leaking and coming apart.

Some of the main hose couplings are bauer couplings, cam and groove, claw couplings, and IBC couplings.