A Hydraulic Hose is designed to transmit pressurised fluids to machinery, but choosing the right hose and hydraulic hose fittings is crucial before purchasing. This can be done through using the STAMPED method.

Size

In order to maintain optimum function, the inside diameter of the hose must be large enough to accommodate hydraulic fluid, whilst minimising pressure loss. This lowers the heat generated by the losses, and reduces the turbulence. Many people in the industry recommend using a Dash Numbers/Dash Sizes measurement to identify the size of the hose fitting. This measurement is the inner diameter in sixteenths of an inch. Please see the Hydraulic Hose Sizing Nomogram.

Temperature

When selecting a replacement assembly, it is important to consider both the ambient temperature and the media temperature. The ambient temperature is the temperature around the hose where it is being used. The media temperature is the temperature of the media conveyed through the hose. The hose that is selected needs to be able to withstand the minimum and maximum temperature of the system. When routing near hot manifolds, a heat shield may be advisable and care should be taken.

Application

When determining which hose is right for you, it is important to know how you intend to use the hydraulic hose. For example:

- What environmental factors will the hose will be exposed to?

- What equipment is the hose going to be used on?

- Fluid compatibility?

- Fluid/Ambient temperature?

- Thread end connection type?

- Working and spike pressures?

- Permanent or field attachable couplings?

- Suction application?

- Routing requirements?

- Thread type?

- Government industry standards being met?

- Unusual mechanical loads?

- Minimum bend radius?

- Non-conductive hose required?

- Excessive abrasion?

There are lots of factors to consider, but determining them takes you one step closer to finding the right hydraulic hose for your purpose.

Material to be Conveyed

Depending on your chosen application, some require oils and chemicals to be transmitted through the system. In this case, the hose needs to be compatible with the fluid used in terms of the inner tube, cover, hose fittings, and O-rings.

Pressure

It is important to know the system pressure, including pressure spikes. Published working pressures must be equal to or greater than the maximum system pressure and any spikes. Having pressure spikes that are greater than the published working pressure will shorten the hose life.

Ends/Couplings

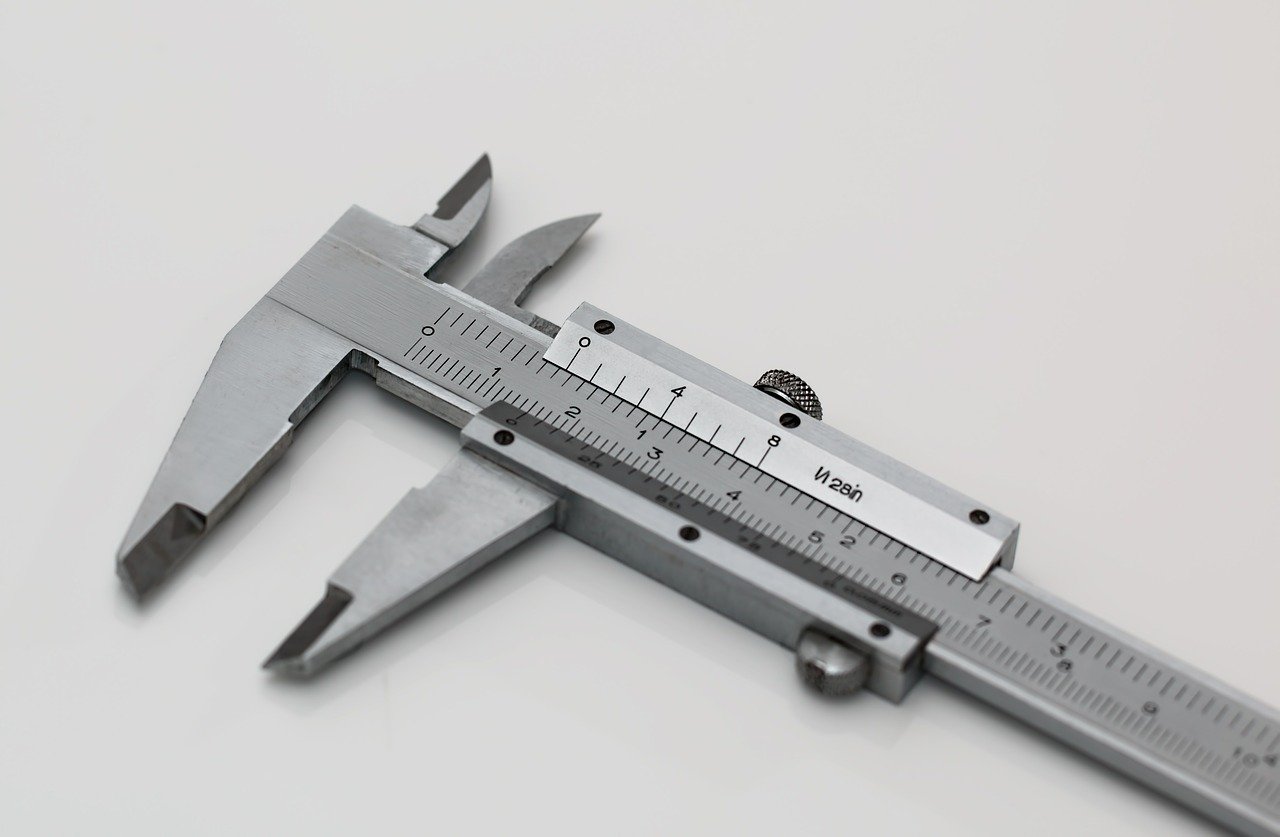

Ends of couplings must be properly matched to their components, to ensure that the connection is leak-proof. Do not mix ‘n match! It is recommended that you choose couplings that are of the same manufacturer as the hose. Hoses and couplings vary between manufacturers, and so mixing manufacturers can lead to assembly failure. Identify the type of threads used by the system, and then choose couplings that are compatible with those types of threads. Determine the seat type: thread interface, O-ring, mated angle or mechanical joint, mated angle with O-ring. Visually identify, and then measure threads.

Delivery

Determining the volume of fluid that is going to pass through the hose helps to determine the size of hose that you need to use. If you choose a hose that is too small, it can lead to increased pressure loss. Choosing a hose that is too large will lead to unnecessary costs and weight.

Hose Shop are the leading supplier of Hydraulic Hoses, get in touch with us and we will help you to find the right Hydraulic Hose for you.