One of the most common questions we receive is ‘can you connect hoses together?’, and following on from this, how to connect a hose. The answer to the above is a resounding yes! You can indeed connect industrial hoses together, and even better, all you need is a few key products, namely BSP fittings and hose couplings; the use of which will ensure secure, safe and reliable connection between hoses.

Read on for a full explanation of what exactly both of these key products are, the role they play in connecting hoses together, and which items you’ll require for your particular industry.

What Is A BSP Fitting?

Also referred to as BSP adaptors, BSP (British Standard Pipe) fittings help connect hoses carrying water, oil and air, and are primarily used in the hydraulic and pneumatic industries for connecting plumbing fittings. BSP fittings are therefore often utilised in the fitting of radiators.

BSP fittings encompass a range of standard screw thread types which come in ‘male’ and ‘female’ variants, and work by joining an internal ‘female’ thread to an external ‘male’ thread. 16 different thread sizes exist, based on the inner diameter of the steel tube in which the thread is intended for, and these sizes range from 1/8 inch to 6 inch. Due to this variety of sizes, BSP fittings are super versatile, and fittings can be found to fit most hoses.

What Are The Different Types Of BSP Fitting, And Which Is For Me?

Gender aside, 2 key types of BSP fitting exist; parallel thread (BSPP) and taper thread (BPST), however BSPP fittings are the most frequently used fitting in the UK.

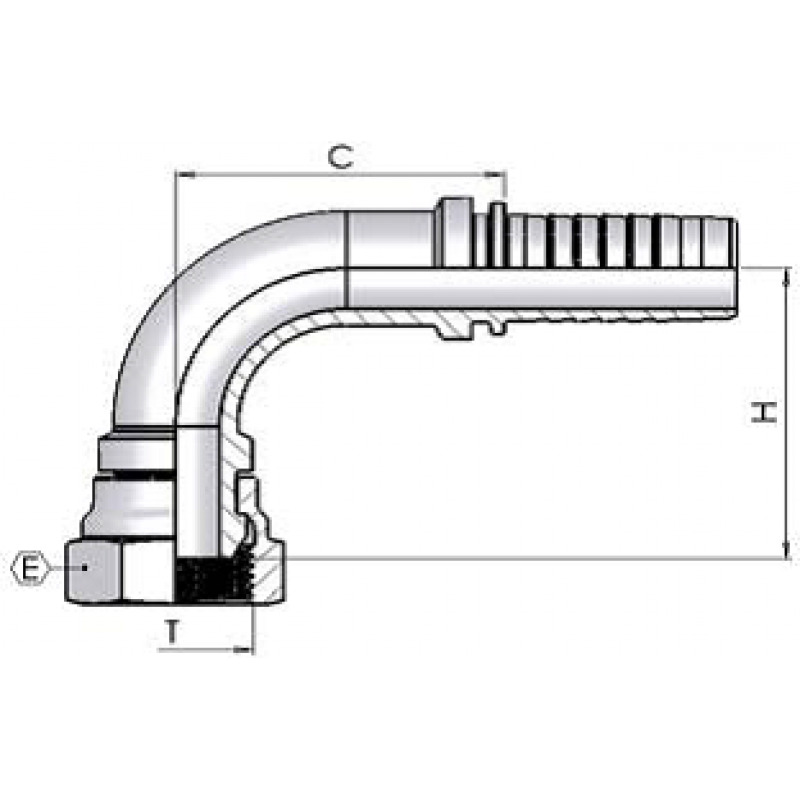

You’ll need to choose a BSPP fitting that fits the specific hoses you are trying to connect. BSPP fittings come in an array of shapes to accommodate various hose types and shapes, including; equal and unequal adaptors, fixed adaptors, swivel adaptors, swept elbows, compact elbows, fixed tees, swivel tees, and bulkheads, amongst others.

The type of BSPP fitting you’ll require to connect your hoses together therefore depends on your male/female requirements (for example, you may require a male/male fitting if you have two female mating parts to attach to), and what shape fitting you require for your hoses.

Aside from BSPP and BSPT fittings, NPT fittings also exist. NPT fittings are predominantly used in North America, whilst BSPT fittings remain popular in China and Japan, with BSPP fittings prevalent across Europe, Asia, Australasia and South Africa. However, the type of fitting utilised does depend on the industry as well as location. For example, pressure systems onboard ships tend to employ BSPP fittings, whereas in the oil and gas industry, NPT can be more common. The following guide is very helpful for differentiating between NPT, BSPP and BSPT fittings.

What Is A Hose Coupling, And Which Should I Use?

A hose coupling does quite literally what it says on the tin. A connector located at the tip of a hose, a hose coupling enables connection between hoses. 2 key types of industrial hose couplings exist; threaded coupling types, and non-threaded coupling types (which can in turn be gendered or genderless).

Of the non-threaded gendered coupling types, three are most widespread; cam and groove couplings, IBC couplings and lever lock water couplings.

Cam and groove couplings (also referred to as camlocks) are available in several materials, including aluminium, brass, polypropylene and stainless steel, and so suitably couple various hoses. They are ideal for leak free, timely and easy connections, and are used often in the water, tanker and agriculture industries, amongst others.

IBC couplings on the other hand are specifically designed to provide safe connections with IBC tanks, and are most commonly used in the agriculture, chemical, and transport industries.

Also created with a particular purpose in mind are lever lock water couplings, which were made for joining large bore hoses. With one of their predominant features being the use of a rubber seal or oil resistant sealing ring, lever lock water couplings are used frequently in the water and agriculture industries, and are attached to hoses using hose clamps.

With industrial hose couplings and BSP fittings explained, you should now have a good idea of the tools required to connect hoses together. For further information on how to connect a hose, or which couplings and fittings best suit your specific needs/industry, please don’t hesitate to get in touch with our team of experts, and we’ll gladly assist you further!

Or, keep reading our blog for further information on everything hose-related, from choosing the right industrial hose size, to the best practices for hose installation.